Secure your workflow with Bitbucket. In many circumstances forces outside of development and IT operations cause the lengthiest delays.

Value Stream Mapping Wikipedia

Value Stream Mapping Wikipedia

Using Lean for Perfection and Quality 3.

Lean value stream mapping. Value stream mapping is a lean management technique for analyzing the flow of materials requirements and data associated with a given process system or product. The course on Value Stream Mapping in Lean Business is part of the Lean for Business Organizations program which includes the following 6 sections. Ad Built for professional teams.

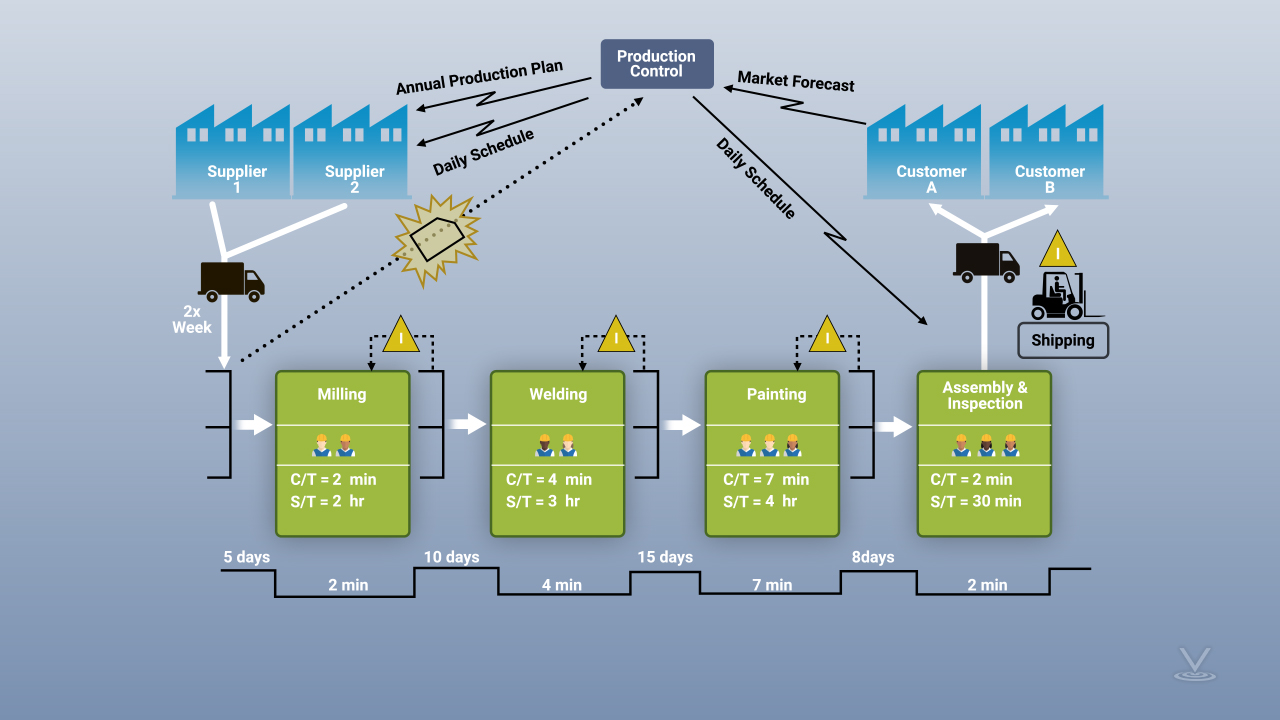

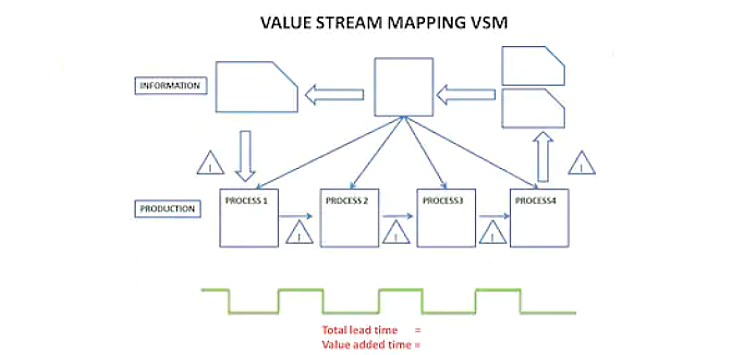

Introduction to Lean for Service and Manufacturing 2. It helps you optimize the way you deliver value to your customers. Value Stream Map VSM A tool used to improve a process by identifying added value and eliminating waste A process map that follows the value creation process strap yourself to the product or service and see where you go A process map with data added Times.

For example if the cycle time reduction is the focus of a process improvement the VSM will display touch time wait time whether the process step is value. The main benefits of value stream mapping are. As such the majority of improvements are of a small but incremental kind as opposed to a radical or breakthrough type.

Value-stream mapping is essentially a language and as with any new language the best way to learn mapping is to practice it. A futurestate map deploys the opportunities for improvement identified in the current-state map to achieve a higher level of performance at some future point. In conclusion Value Stream Mapping is a fundamental lean tool but its application doesnt always lead to the expected result.

Value Stream Mapping VSM is a lean management technique used to analyze the flow of materials and information currently required to bring a product or service to a Customer. In Lean Value stream mapping is a tool of significant importance for achieving continuous improvement of the way you work. As with other business process mapping methods it helps with introspection understanding your business better as well as analysis and process improvement.

Number of rejects. Ad Built for professional teams. It does it in such a way that everyone can easily see where improvements can be made to increase efficiency and throughput and therefore reduce lead-time and costs.

Value stream mapping is a technique developed from Lean manufacturing that organizations use to create a visual guide of all the components necessary to deliver a product or service with the goal of analyzing and optimizing the entire process. Lean value stream mapping helps organizations visualize then reduce these waiting periods. Processing wait cycle Quality.

Lean Tools and Techniques for Flow and Pull. Wikipedia The inputs for a values stream map include all the resources you. Value stream mapping is a lean management tool that helps visualize the steps needed to take from product creation to delivering it to the end-customer.

The seven value stream mapping tools 49 in a kaizen-style system. For example an application update might require approval from business stakeholders before it can move from design to development. In some cases it may be appropriate to draw an ideal-state map showing the opportunities for improvement by employing all known lean methods including right-sized tools and value-stream.

A Value Stream Map VSM is a visual tool that displays critical data and information relevant to the improvement focus of a process. Waste removal inside value streams As the focus of the value stream includes the complete value. Value Stream Mapping VSM is a lean manufacturing tool that allows you to see all the steps involved in a group of processes.

The goal of value stream mapping is to reduce the end-to-end lead time of a process by highlighting and eliminating sources of waste as well as by building processes and value chain where the individual process steps. VSM requires strong communication. It allows you to visualize and bound your process.

Using the Mapping Tool Value-stream mapping can be a communication tool a business planning tool and a tool to manage your change process. Secure your workflow with Bitbucket. I hope this article helps you to avoid some of the most common pitfalls lean companies encounter when they try to implement it.

Mifd Lean Manufacturing And Six Sigma Definitions

Mifd Lean Manufacturing And Six Sigma Definitions

Lean Manufacturing Value Stream Mapping Online Training

Lean Manufacturing Value Stream Mapping Online Training

10 Easy Steps To Complete A Value Stream Map Vsm

10 Easy Steps To Complete A Value Stream Map Vsm

What Is Value Stream Mapping In Lean Manufacturing Convergence Training

What Is Value Stream Mapping In Lean Manufacturing Convergence Training

Peta Aliran Nilai Wikipedia Bahasa Indonesia Ensiklopedia Bebas

Peta Aliran Nilai Wikipedia Bahasa Indonesia Ensiklopedia Bebas

Lean Simulations Value Stream Map Examples Value Stream Mapping Lean Manufacturing Process Map

Lean Simulations Value Stream Map Examples Value Stream Mapping Lean Manufacturing Process Map

What Is Value Stream Mapping Vsm Benefits Process And Value

What Is Value Stream Mapping Vsm Benefits Process And Value

Value Stream Mapping Explained Lean Six Sigma Training Guide Copy

Example Of A Value Stream Map Current State Map From Lean Management Download Scientific Diagram

Example Of A Value Stream Map Current State Map From Lean Management Download Scientific Diagram

Apples Oranges Value Stream Mapping In A Low Volume High Mix Environment

Apples Oranges Value Stream Mapping In A Low Volume High Mix Environment

Value Stream Mapping Job Shop Lean Manufacturing

Value Stream Mapping Job Shop Lean Manufacturing

Value Stream Mapping Value Stream Mapping Lean Six Sigma Process Flow Chart

Value Stream Mapping Value Stream Mapping Lean Six Sigma Process Flow Chart

Value Stream Map Template Example Value Stream Mapping Flow Map Map

Value Stream Map Template Example Value Stream Mapping Flow Map Map

No comments:

Post a Comment