Kaizen originated in Japan shortly after the end of the Second World War. With its roots in manufacturing continuous improvement is a method that strives to locate opportunities for ensuring efficiency continuously.

Continuous Improvement Model Continual Improvement Tools Asq

Continuous Improvement Model Continual Improvement Tools Asq

Continuous Improvement Method Implemented.

Continuous improvement methodologies. Business Process management is a methodology for continuous improvement. Unlike the other process improvement methodologies weve mentioned so far this ones a bit more hands-on. Explained shortly it is a never-ending strive for perfection in everything you do.

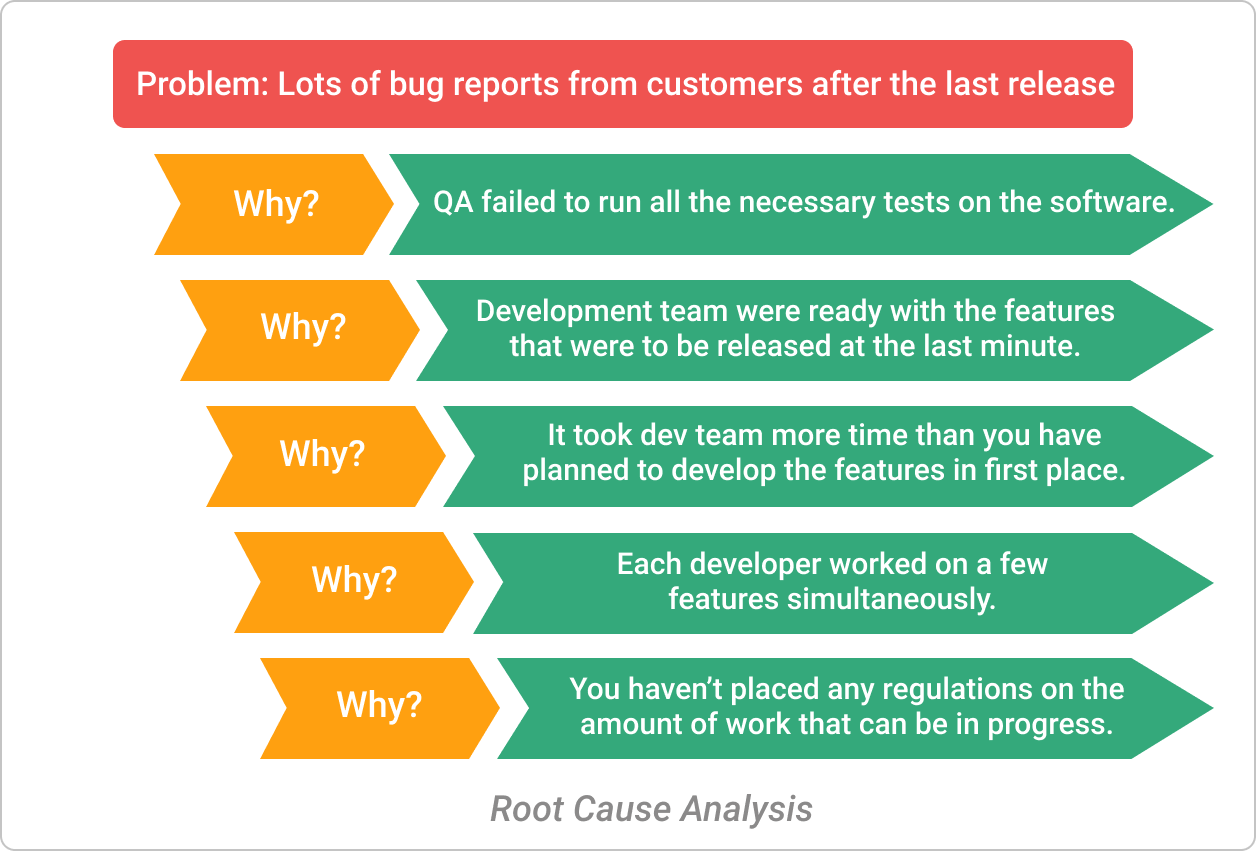

Here is the list of commonly used methodologies or approaches for continual improvement. PDCA stands for Plan Do Check and Act. The PDCA cycle comes from the Kaizen philosophy of continuous improvement.

The Continuous Improvement Model. The main idea behind it is that you should be constantly analyzing and optimizing business processes. PDCA or PDSA cycle was developed by quality guru Walter Shewhart and was later made famous by Dr.

Unlike the other process improvement methodologies weve discussed so far this one addresses the entire spectrum from start to finish. Whereas process and value stream mapping aid strategic planning PDCA cycles support improvement efforts from start to finish. This is done surprise surprise by periodically examining and improving your processes to smash bottlenecks use the best software and take advantage of the most efficient methods.

Total Quality Management TQM. An organization-wide effort focused on continuous improvement to improve customer quality. However it would appear that each decade seems to herald another version of continuous improvement tools and methodologies for corporates to embrace en-masse with the assistance of consultants.

This involves the assessment of current processes products and services to ensure that output is maximised and waste is minimised. Continuous improvement is a method to make sure that your processes methods and practices are as efficient accurate and effective as possible. Methodology centered around reducing inventory costs manufacturing products only as theyre needed.

A combination of Lean and Six Sigma methodologies. Lean and Six Sigma. In Lean management continuous improvement is also known as Kaizen.

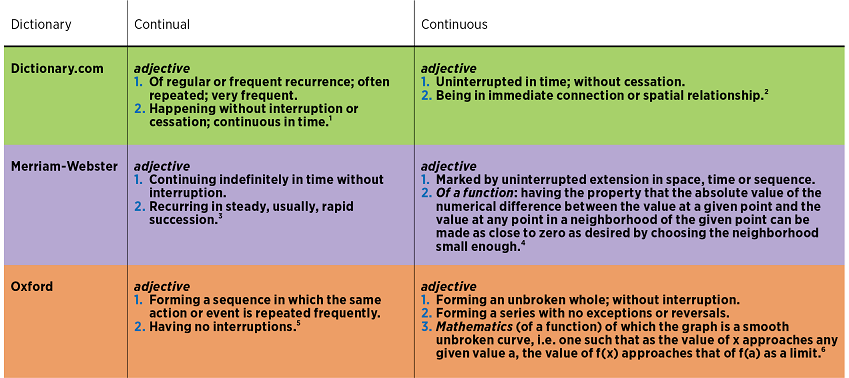

The term continuous improvement can be very abstract if not placed in a specific context. The end result is virtually the same for a significant number of companies a couple of early wins and not much else to show for the efforts that have.